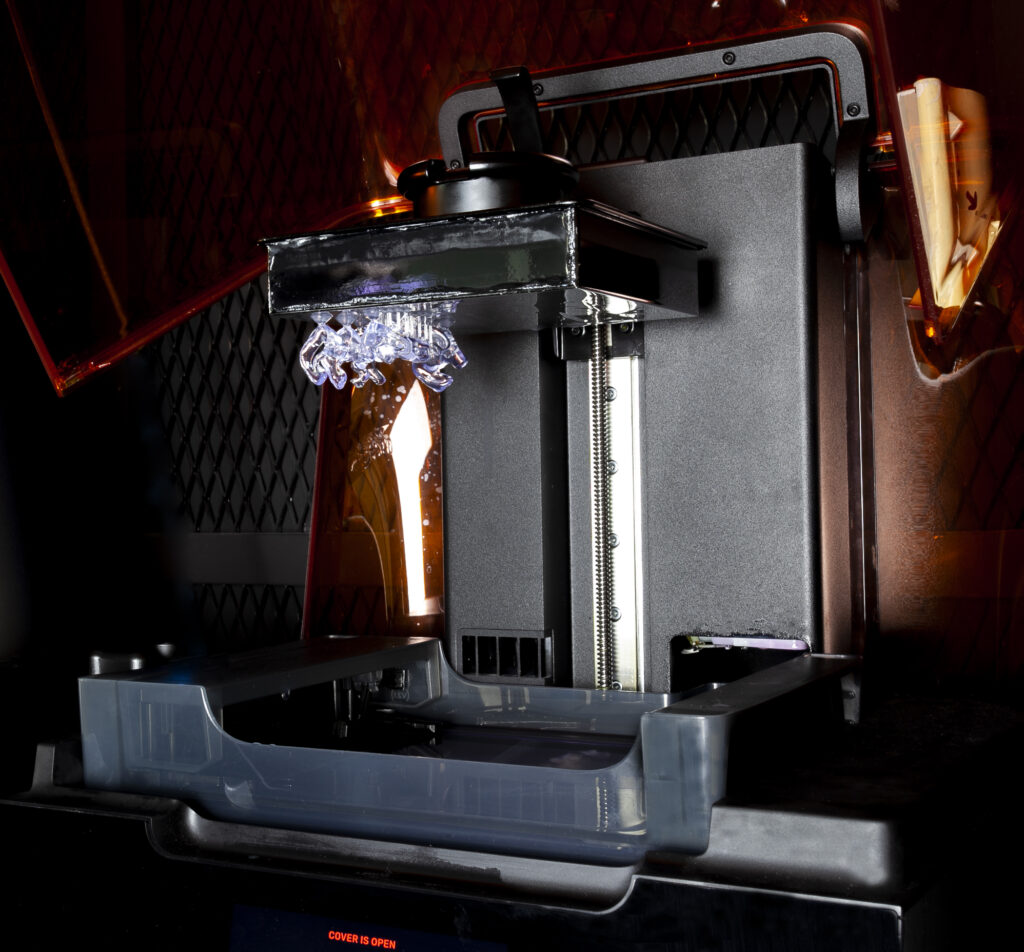

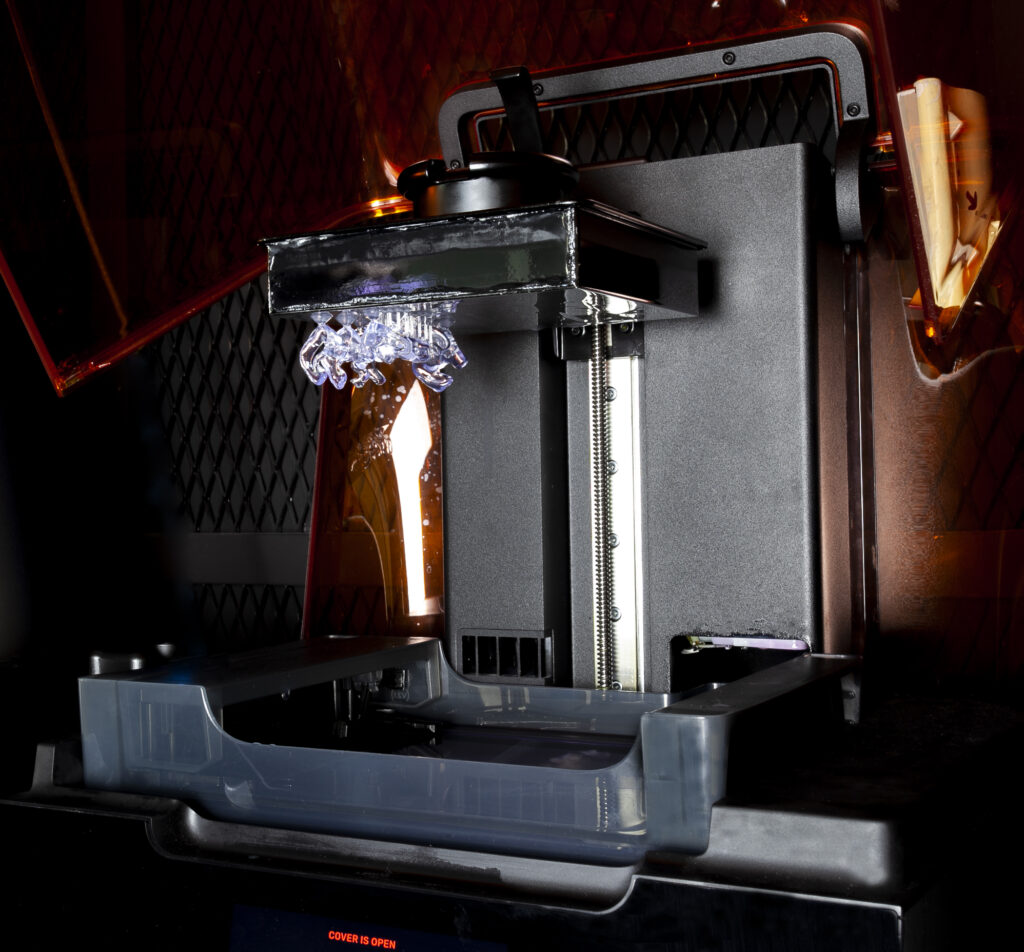

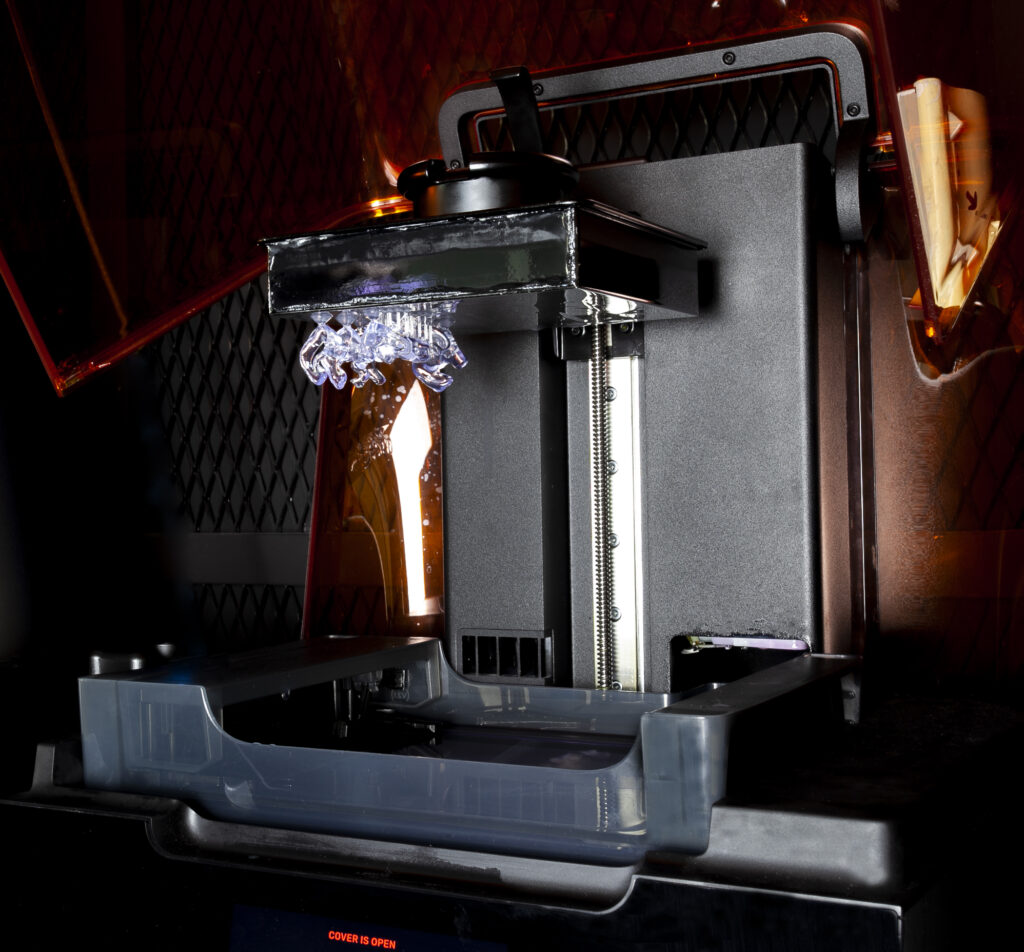

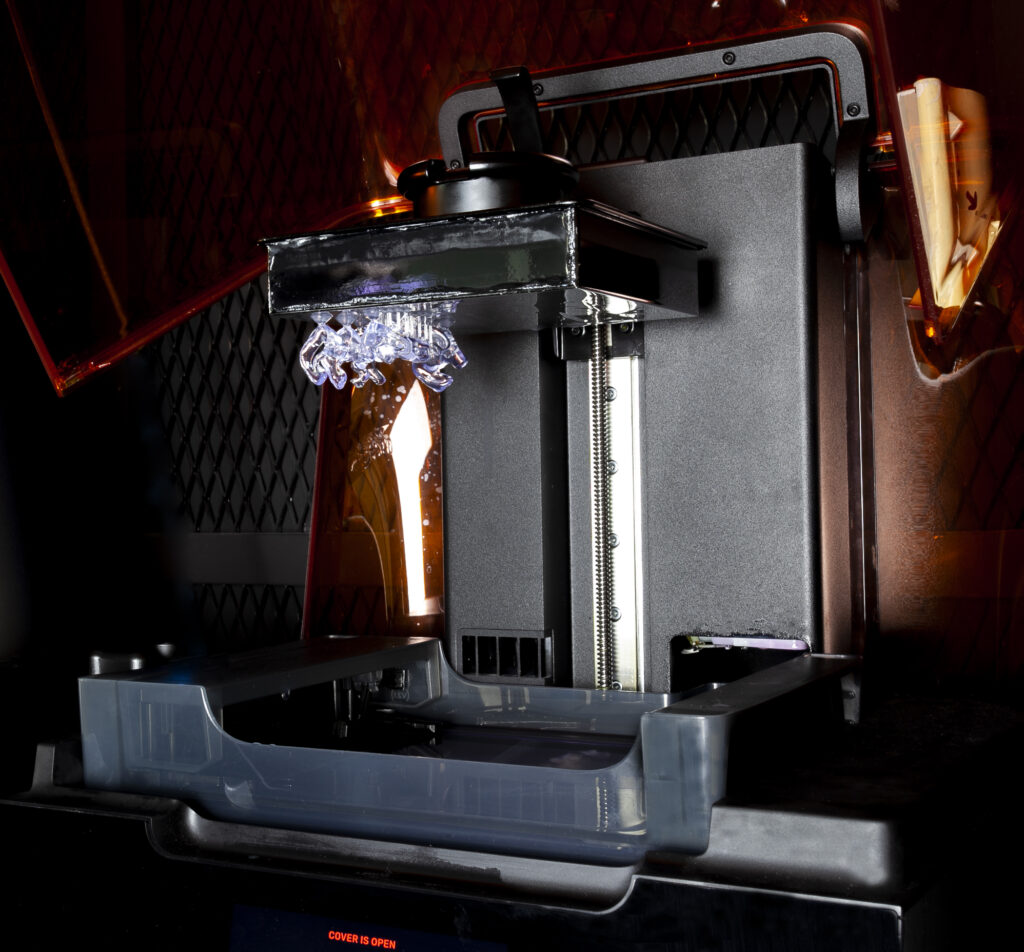

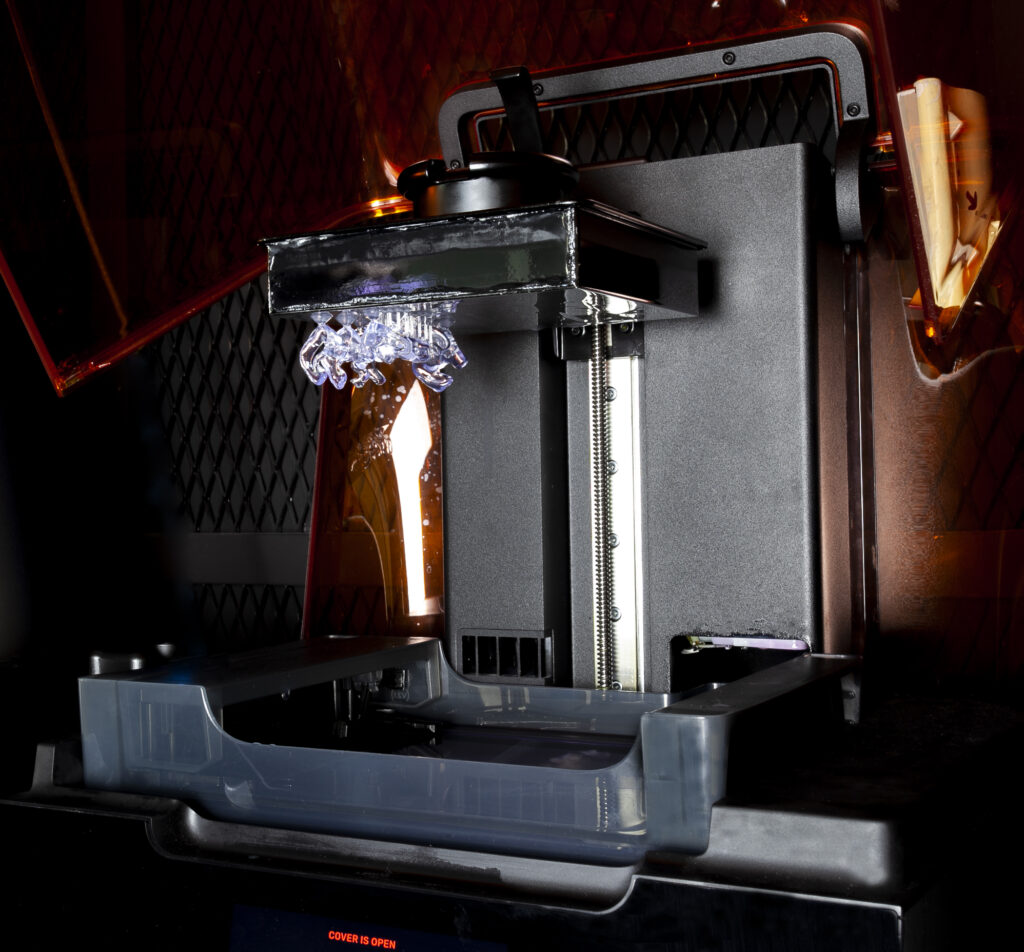

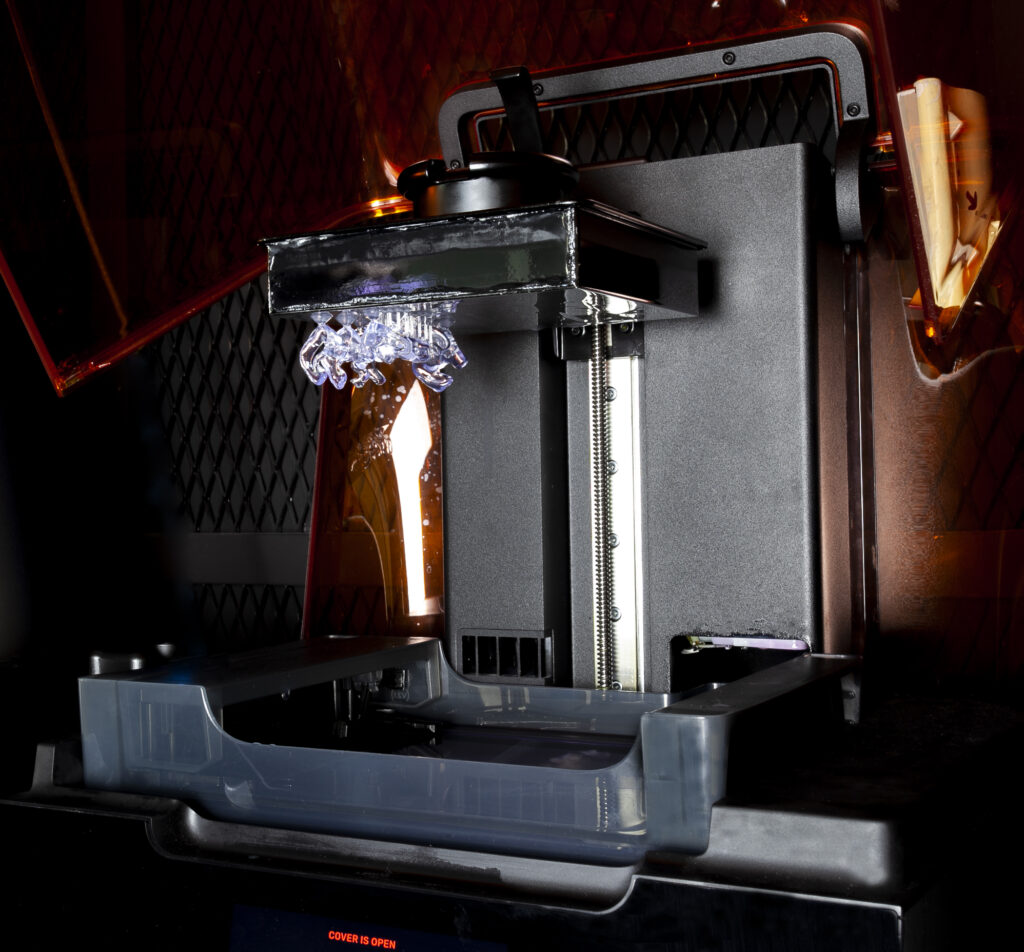

In our ISO-certified facilities, we utilize digital production techniques to create ear molds. This allows us to easily reproduce models and produce multiple variations without the need for additional ear impressions. Our production process is fully automated and controlled by computer programs, ensuring that each product meets the highest standards of quality and precision. Using state-of-the-art 3D printing technology, we are able to produce ear molds that are at the forefront of the industry.

Our Titanium earmolds are made with the same care and precision as our other earmolds, but with the added benefit of being made with titanium. This durable, lightweight, and biocompatible material is perfect for those who have allergies or sensitivities to standard earmold materials. Additionally, its fine structure ensures a comfortable fit, making it ideal for long-term use. It is widely used in aviation and modern medicine. The titanium earmolds will bring you not just the comfort but also the confidence for the daily use.

Our 3D printed ear molds can be customized with a variety of different colors using specialized pigments. We offer a range of 10 different color options to suit the preferences of our customers, making sure they are able to get the perfect look for their ear molds while also maintaining their high level of accuracy.

Our ear molds are designed to be as comfortable as possible for our patients. For patients with flattened or narrowing ear canals, we use special materials to increase grip and make it easier for the ear molds to stay in place. These materials give the surface of our acrylic ear molds a shape similar to silicone ear molds, which helps to keep the molds securely in the ear.

In our digital ear molds, we create an open area specifically designed to hold the receiver. This allows for easy attachment and removal of the receiver without any additional modifications to the ear mold. Our ear molds are designed with precise tolerances to ensure a secure fit for the receiver without the need for adhesive. For RIC (Receiver-In-Canal) ear molds, we use computer-aided design to model the receiver and create the mold. In addition to an ear impression, we will also require the receiver itself in order to complete the production process. Once the ear molds are complete, we will assemble them and deliver them in a ready-to-use state for your patients.

Our team of expert engineers, trained in Europe and America, and our use of digital production methods have greatly improved our ability to create ear molds. If an ear mold should fall out of the ear, we use the Wing Lock attachment to provide additional support and hold the mold in place, preventing it from falling out. This support is given in the concha region of the ear.

If you want to benefit from our digital ear mold production, you can send us your ear prints through our contracted couriers. After your ear prints reach us, our experts will complete the design and production processes and send you your ear molds produced on 3D printers within 2 business days

If you have a scanned image of your ear mold, you can use our Automatic Modeling module, which uses the world’s most advanced algorithms, to create your ready-to-produce ear mold. The ear molds designed with our automatic modeling module will be sent to you within 2 business days.

Earfit additive manufacturing allows customization in many products.