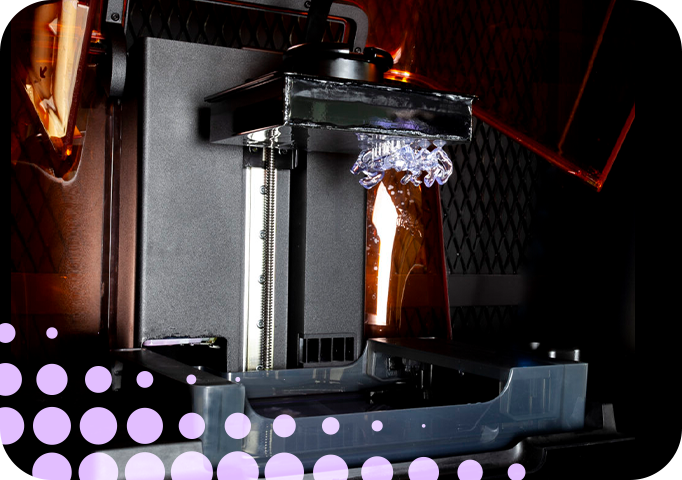

EarFit employs polymer-based SLA (Stereolithography) technology to achieve high-precision and detailed production in the manufacturing of our earphones. SLA technology works by solidifying liquid polymer resin layer by layer using laser light, making it unrivaled in creating complex geometries and intricate details.

All machines used in our production processes are CE certified, and the resins used are specially developed for audiology applications, ensuring biocompatibility and reliability. This ensures that every earphone is manufactured to the highest quality standards and fully meets the needs of our users.

Earfit was founded in 2019 with a mission to bring the power of music and sound to everyone. We specialize in custom earphones and advanced acoustic solutions, providing users with a unique audio experience.

ODTÜ Teknokent Silikon Blok No: ZK-01, 06800 Çankaya/Ankara

284 Chase Road A Block 2nd Floor Unit 100 Southgate London/England